| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 380V |

| Automation Grade | Automatic |

| Reactor Up to | 500-liter Capacity |

| Click to view more | |

Product Details

Ablaze offers in various sizes of reaction distillation units (Borosilicate Glass Flask) 20 Liter, 50 Liter, 100 Liter, 200 Liter & 500 Liter and is suitable for operation under atmospheric pressure/vacuum. We are leading Manufaturer & Suppliers of Reaction Distillation Pilot Plants Glass Reactor in India.

The distillation cycle is used as a thermal separation method, if the chemical composition of the vapor-phase is different from the chemical composition of the liquid-phase. It applies especially to material mixtures with different boiling points, meaning different volatility. Design of processes and plants for the separation, purification, concentration and recovery of chemical components by distillation if one of our skill sets.

Reaction Distillation is the process of separating the components or substances from a liquid mixture by using selective boiling and condensation.

Reaction Distillation may result in significantly complete separation (nearly pure components), or a partial separation may result in an increase in the concentration of selected components in the mixture. The technique can be useful for controlled reactions including hydrolysis and thermal decomposition.

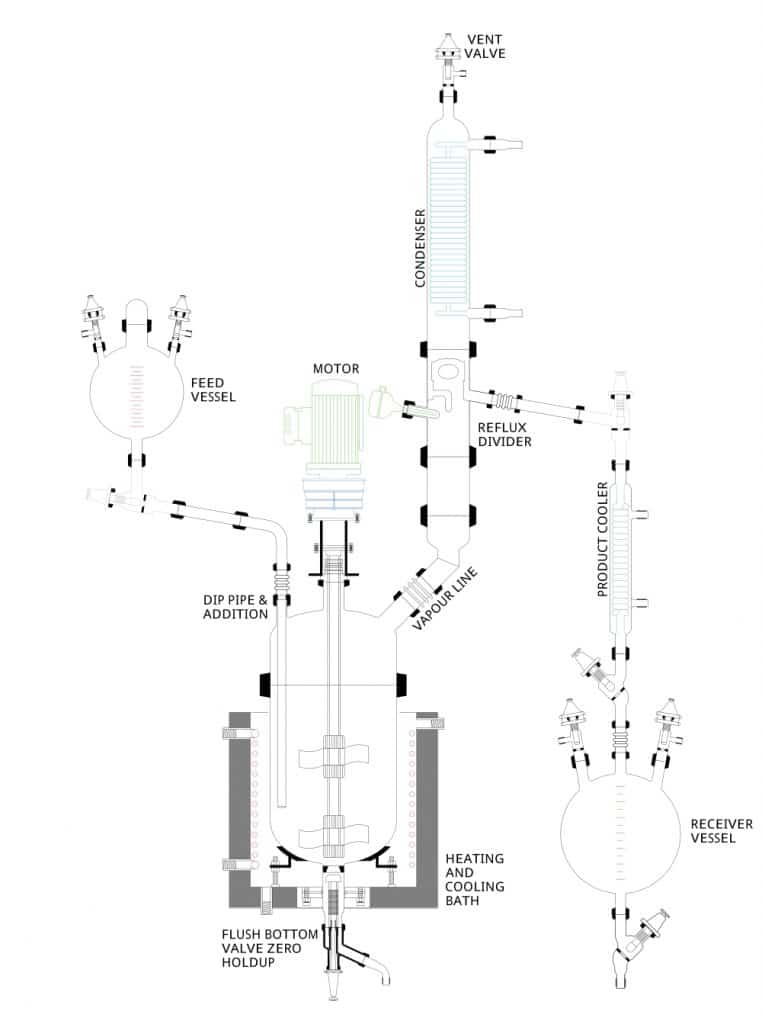

This system is used to carry out stirred reactions and for the quick distillation of reflux. In a heating cooling bath, the reaction vessel is placed and fitted with the addition of a condensation vessel and a motorized stirrer. The material is sub-cooled and stored in a receiver flask.

Salient Features :

- Reactor up to 500equest

Diagram

Dimension Table

| DESCRIPTION | ARDU 50 | ARDU 100 | ARDU 200 | ARDU 500 | |

| Reactor Nominal Capacity | ltr. | 50 | 100 | 200 | 500 |

| Heat Exchanger (Exchange Surface) | m2 | 0.5 | 1.5 | 2.5 | 5 |

| Bath Heater Capacity | kW | 6 | 8 | 12 | 18 |

| Vessel Design Pressure | bar(g) | -1 to +6 | -1 to +0.5 | -1 to +0.4 | -1 to +0.3 |

| Plant Working Temperature | ºC | -20 to +180 | -20 to +180 | -20 to +180 | -20 to +180 |

| Plant Design Temperature | ºC | -25 to +200 | -25 to +200 | -25 to +200 | -25 to +200 |

| Plant Working Pressure | bar(g) | 0.5 | +0.4` | 0.3 | 0.2 |

| Feed Vessel | No. × ltr. | 1 × 5 | 1 × 10 | 1 × 20 | 1 × 50 |

| Receiver Vessel | No. × ltr. | 2 × 5 | 2 × 10 | 2 × 20 | 2 × 50 |

| Rupture Disc | bar(g) | 0.5 | 0.5 | 0.5 | 0.5 |

| Stirrer Speed | rpm | 20 to 250 | 20 to 250 | 20 to 250 | 20 to 250 |