| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Application | Food Industry, Pharmaceutical Industry |

| Color | Blue |

| Click to view more | |

Product Details

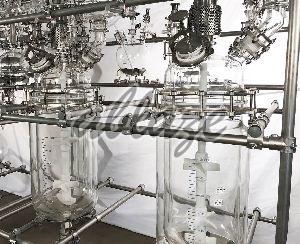

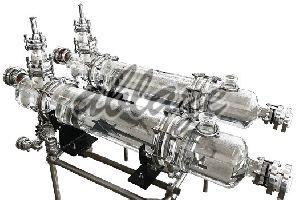

The TFE series Agitated Thin Film Evaporator has proven its efficiency as a device used for the distillation and the evaporation processes, where a scraper system is used to force the process of liquid film-forming. It can successfully undertake several unit operations together, such as defoaming reactions, deodorization, cooling, heating, and much more. Also, you can use it for the recycling process of the organic solvents found from industrial waste. The Agitated Thin Film Evaporator is commonly used in the food industry, pharmaceutical industry, light industry, environmental protection industry, petrochemical industry, and many more.

Instrumental Features

- The scraper system pushes the liquid from a thin film through the rotation process, and hence it provides the appropriate evaporation efficiency and also reduces its operating time.

- The high-precision pipe made from glass allows the liquid to create a unified thin film over the hot surface.

- The Scraper system is built of SUS 316L and PTFE; all the other parts that come in contact with the liquid or gas are usually created from high borosilicate glass 3.3 and PTFE, as both the elements have an excellent corrosion resistance properties.

- The principle evaporation compartment is built from high borosilicate glass 3.3, which allows you to observe the process closely and clearly.

- You can control the temperature and keep it to the absolute level. The Agitated Thin Film Evaporator can reach up to 260°c temperature.

- We have a Self-cleaning roller Model film-forming system available with us. You can apply it to TFE-150, TFE-200, and TFE-300 models.

- We can make the most significant size up to DN300, which can help you reach an effective evaporation area of 0.6 meters Sq.

- A Self-cleaning roller Model, as well as the Scraper Model film-forming systems, are available with us.

- We also have Stainless steel material used in manufacturing the distillation barrels.

Benefits of Wiped Film Evaporator or Agitated Thin Film Evaporator

- The Wiped Film Evaporator has a highly specific heat transfer capacity.

- It has a short residence time.

- It has a low-pressure drop capacity.

- It can operate under low vacuum scenarios.

- It has recorded the evaporation ratios up to greater than 95% without any recirculation.

- It is highly capable of processing high viscosity products.

- It is capable of processing the systems that create the deposits.

- It is super easy to clean.

Applications of Wiped Film Evaporator or Agitated Thin Film Evaporator

- Wiped Film Evaporator can be installed to carry out the evaporation process without any mass transfer.

- It helps in moderating the evaporation ratios.

- You can apply or use the Wiped Film Evaporators for the viscous products.

- You can use it to feed the streams that contain solid particles.

- You can use the Wiped Film Evaporator to attain the high evaporation ratios of almost more than 95%.

- It can be applied to stripping.

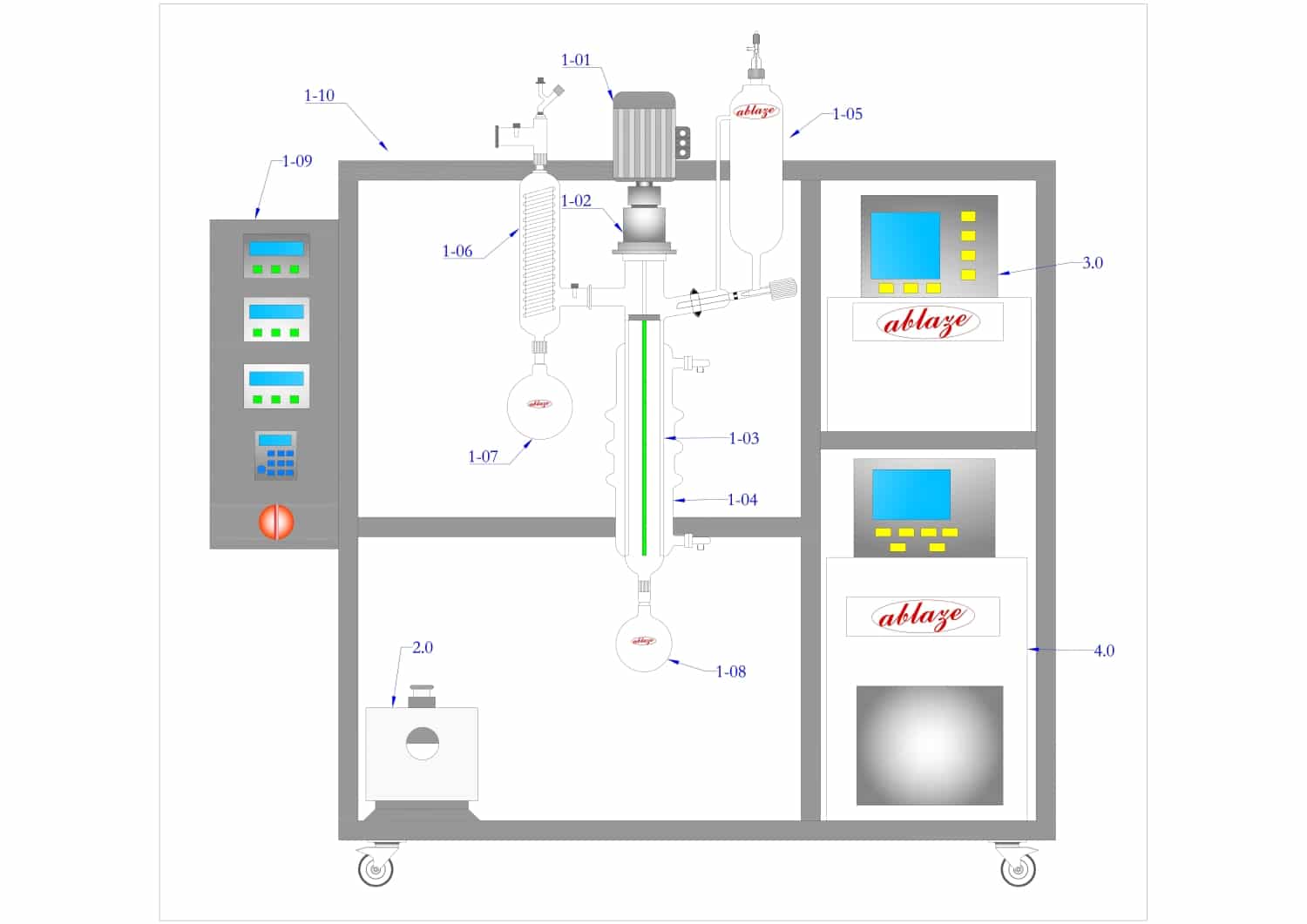

Diagram

Dimension Table 1

| Mark | Specification |

| 1 | Thin Film Evaporator TFE Model Series |

| 01-Jan | Frequency Conversion Deceleration Motor |

| 01-Feb | Magnetic Force Transmission & Completed Sealing System |

| 01-Mar | Wiped Film Forming System |

| 01-Apr | Thin Film Evaporator Main Body |

| 01-May | PTFE Double Vacuum Valve- Dropwise Constant Pressure Feeding Funnel |

| 01-Jun | External Condenser |

| 01-Jul | Light Component Receiving Flask |

| 01-Aug | Heavy Component Receiving Flask |

| 01-Sep | Electrical Control Cabinet |

| 01-Oct | Removable Stainless-Steel Square Tube Frame |

| 2 | Vacuum System |

| 3 | Constant Temperature Heating Circulator System |

| 4 | Low-Temperature Cooling Circulator System |

Dimension Table 2

| DESCRIPTION | ATFE-60 | ATFE-80 | ATFE-100 | ATFE-150 | ATFE-200 | ATFE-230 | ATFE-300A | ATFE-300B | ATFE-300C | |

| Effective Evaporation Area | m2 | 0.05 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 | 0.8 | 1 | 1.5 |

| External Condensation Area | m2 | 0.2 | 0.25 | 0.3 | 0.6 | 0.6 | 0.6 | 1 | 1 | 1.5 |

| Barrel Inner Diameter | mm | 60 | 75 | 100 | 150 | 190 | 220 | 285 | 285 | 285 |

| Constant Pressure Feeding Funnel | L | 1 | 1 | 2 | 2 | 5 | 5 | 10 | 10 | 20 |

| Processing Flow | L/H | 0.5~3.0 | 1.0~5.0 | 2.0~8.0 | 3.0~15.0 | 5.0~20.0 | 6.0~22.0 | 8.0~25.0 | 10.0~30.0 | 12.0~35.0 |

| Motor Power | W | 120 | 120 | 120 | 120 | 120 | 200 | 200 | 200 | 200 |

| Max Rotation Speed | rpm | 450 | 450 | 450 | 450 | 300 | 300 | 300 | 300 | 300 |

| Constant Pressure Feeding Tunnel | L | 1 | 1 | 2 | 2 | 5 | 5 | 10 | 10 | 20 |

| Light Component Receiving Flask | L | 1 | 1 | 1 | 2 | 3 | 5 | 10 | 10 | 20 |

| Heavy Component Receiving Flask | L | 1 | 1 | 2 | 3 | 5 | 10 | 20 | 50 | 50 |

| Vacuum System | L/H | 4 | 4 | 4 | 8 | 8 | 15 | 15 | 15 | 15 |

| Constant Temperature Heating Circulator System | Cº | 5 L/300 ℃ | 10 L/300 ℃ | 10 L/300 ℃ | 10 L/300 ℃ | 20 L/300 ℃ | 30 L/300 ℃ | 30 L/300 ℃ | 30 L/300 ℃ | 30 L/300 ℃ |

| Low Temperature Cooling Circulator System | Cº | 5 L/- 10℃ | 5 L/- 10℃ | 5 L/- 10℃ | 5 L/- 10℃ | 20 L/- 10℃ | 30 L/- 10℃ | 30 L/- 10℃ | 30 L/- 10℃ | 30 L/- 10℃ |