| Business Type | Manufacturer, Exporter, Supplier |

| Type | Bromine Recovery Plant |

| Application | Industrial |

| Automatic Grade | Automatic |

| Click to view more | |

Product Details

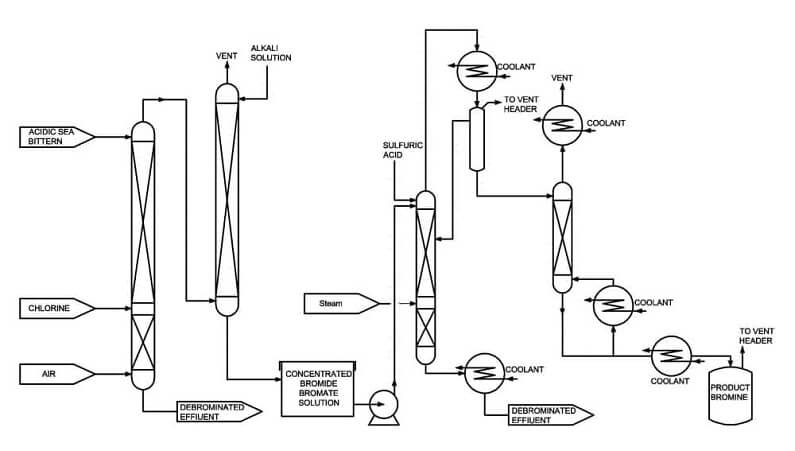

The acidified feed containing Bromide salts is fed to Reactioncum- Air blowing tower, where dry Chlorine gas and Low-Pressure Air are injected. The Chlorine gas liberates free Bromine which is stripped out by Air in form of vapors. These vapors enter Absorption tower where Alkali solution is circulated and a Bromide-Bromate solution is formed. The Bromine content in the resultant solution is highly enriched compared to the original content. The unabsorbed air is vented out.

The enriched Bromide-Bromate solution is subjected to acidification in the liberation tower, where Bromine vapors are liberated and stripped out by steam injected at the bottom of the tower. The vapors leave the top of the tower.

These vapors are condensed in a series of condensers, and condensate is collected in the phase separator. The water phase is separated from Bromine and is refluxed to the tower. The Bromine so separated is Crude Bromine and is subjected to distillation.

Under distillation, Chlorine is removed and pure Bromine collected as bottom product. This Bromine is cooled through Product coolers and collected in product receiver/s. A Vent condenser condenses most of the Bromine and recycles into the system. The non-condensable are taken to the Vent scrubber.

The dibrominated effluent from the Air blowing tower may be taken for neutralization and effluent treatment.

Bromine finds its application directly and indirectly in the manufacture of pesticides, agrochemicals, pharmaceuticals, fire-retardants, photography chemicals, and many others. Bromine occurs in nature as Bromide salt present in seawater and in-land brine which is used for the grassroots production of Bromine. It is also recovered from industrial effluents/ byproducts where it occurs as different Bromide salts. Ablaze has a long and successful record of design and supply of several Bromine Recovery Plants – both grass-roots and from industrial effluents. Being manufacturer of Borosilicate Glass equipment, PTFE components and PTFE lined components, Ablaze is well qualified to handle such recovery systems as these are the major Material of Construction used in such systems. Custom made designs are offered for various Bromine Recovery Plants, depending on the source of Bromide and the end use of final product Bromine. Typical Product quality for Bromine recovered from such recovery plants is as follows:

- Bromine 99.5% w/w min

- Chlorine 0.3% w/w max

- Moisture 0.1% w/w max

However, the system can be designed to give the desired product quality as per the customer requirement. For eg. system can be designed to give dry Bromine if so required. There are two established Processes for the Recovery of Bromine from aqueous Bromide solutions.

Diagram