Filtration

Leading Manufacturers, Exporters, Wholesaler, Retailer of Glass Nutsche Filter and Glass Mixer Settler from Vadodara.

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Capacity | It Comes with a Variety of Working Capacity from 5 Liters to 200 Liters Jacketed While a 400-liter Variant Comes with a Single Wall. |

| Temperature | It Can Handle Up to 200ºc of Temperature. |

| Filter Cloth | It Comes with a Variety of Mesh Sizes and Moc that are Available as per Request. |

| Construction Material | It is Built with Borosilicate Glass and Ptfe |

The Agitated Glass Nutsche filters are commonly used in the following industries for the production purposes, chemical industry, pharmaceutical industry, and laboratory industries, and many others. (ANFD) Agitated Nutsche Filter Dryer Manufacturer produces the ANFD’S for the purpose of filtration as well as drying the material in the same unit.

The Glass Nutsche Agitated Filters are designed specifically for efficient filtration to allow for liquid to Solid- Separation, it can be comfortably combined with our regular reaction unit. Both contact parts are inert and thus permit a range of pharmaceutical, chemical, and solvent equipment to be used. An appropriate filter is used to separate the solid particles of the slurry, forming a filtered cake. The Filtrate Flows downwards and can be obtained from the valve at the bottom outlet, Also easily remove the filter Cake.

Agitated Glass Nutsche Filters are commonly used in herbal medicines, cosmetics, kilo-Laboratory, pharmaceutical and agrochemical industries as well as food industries.

Non-Jacketed Glass Nutsche Filters sized up to 400 Liters

Glass Jacketed Nutsche Filters size 5 Liter up to 100 Liters.

Primary Features :

- With the same production capacity, the price of S.S system is 1.5-2 times than glass one.

- Installation of Glass one is easier. It can be finished in 1 hour with two people.

- Delivery time of Glass one is usually 20 days, while S.S one usually in 60 days or longer.

- Glass one is lighter, small space occupied and easy to move. Glass one is visible and can adjust the condition of the experiment quickly and accordingly.

- The anti-corrosion ability of Glass one is stronger than the S.S SPD system.

- While in R&D or pilot produce procedure, glass SPD system is better; While in large-scale production, you can choose S.S one.

Advantages :

- Transparency offers visibility of processes.

- Possible vacuum filtering.

- Recovery of very high solvents.

- At the ambient level, nitrogen spills into the reactor.

- Very High Filtration Efficiency.

- Safety is ensured, and surfaces of heat transfer may be given to preserve filtration temperature.

- Solvents remain in the closed structures and so no harmful vapors in the environment remain released.

Applications :

- It can be applied for Heating & Drying process

- It can be used for Solid & Liquid Separation process

- It can be used for the Crystallization process

- It can be used for the Filtration process

- It can be used for Chromatography

- It can be used for Solid Phase Peptide Synthesis (SPPS)

Commercial Uses

Agitated Nutsche filters are commonly used in the following industries for the production purposes; chemical industry, pharmaceutical industry, and laboratory industries, and many others. (ANFD) Agitated Nutsche Filter Dryer Manufacturer produces the ANFD’S for the purpose of filtration as well as drying the material in the same unit.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial Use |

| Voltage | 220V |

| Frequency | 50Hz |

| Driven Type | Electric |

| Automation Grade | Semi-automatic |

| Material | Glass |

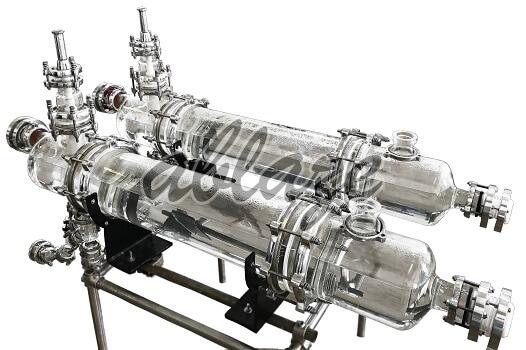

The MIXER -SETTLER is a revolutionary new device, which makes phase separation automatic and simple, irrespective of the concentration of two phases (interface height). The mixer-settler is the name given to a type of EXTRACTOR made up of a number of mixing and settling chambers connected alternately in series. In the mixing chambers, optimum mass transfer is achieved by through mixing of two phases with the aid of pumps and stirrers. In the simplest case, the MIXER -SETTLER consist of an adjustable overflow valve, stirrer drive assembly and settling zone.

The Mixer Settler has a wide application in the Process Industry , Particularly in

- Azeotropic Distillation

- Extractive Distillation

- Steam Distillation

- Esterification Distillation

Stirrer Drive Assembly

The mixing chamber consists of a cylindrical glass cover in which a variable speed stirrer drive is fitted. Glass impeller Stirrer creates a negative pressure at the inlet, which can be used to draw liquid from a previous stage in the process. In the mixing zone, a turbine stirrer with variable speed unit mixes the two phases and the mass transfer takes place during dispersion.

Separation Zone

Separation of phases takes place in two phases. Firstly, The turbulent flow in the mixing zone must be brought under control and converted into axial flow. Then the mixer passes into the separation zone where the two phases separate, due to their specific gravity difference.

Auto Continuous Separation

The adjustable overflow valve assembly at one end of the vessel can be set for any interface height. The position of the overflow weir is adjusted to suit the relative densities of the two phases. This valve can be operated externally such that the interface height can be set or reset depending on the operating process conditions. The separating head incorporates an internal overflow weir, which is manually adjusted using a hand wheel.

Visual Monitoring

The transparency of Borosilicate glass facilitates the adjustment of the overflow valve by visual monitoring whereby any change in the process conditions resulting into a change in layer (interface) height can be immediately adjusted by resetting the overflow valve. The resetting of the separation height is very simply achieved by rotating the hand wheel of the overflow valve assembly in the clock or anti-clock direction.

Large Interface Plane Area

The horizontal glass vessel of the MIXER-SETTLER provides a large interface area of separation two immiscible liquid phases for a given volume. This enhances the efficiency of the separation process.

Overview Of The System

The system consists of the following adjustable overflow valve, stirrer drive assembly and settling zone.