| Business Type | Manufacturer, Exporter, Supplier |

| Application | Water Distillation |

| Weight | 100-1000kg |

| Voltage | 380V |

| Click to view more | |

Product Details

The Short Path Molecular Distillation system is primarily used in pilot or lab-scale production. Particularly, to compile the parameters from the experiments before moving into production.

The Glass Short Path Distillation System (SPD) has the following advantages over the Stainless Steel Short Path Distillation System (SPD);

Following Advantages :

- Concerning the same production capacity, the price of a Stainless Steel SPD system is almost twice as compared to the Glass SPD system.

- Installation of the Glass SPD system is a lot easier as it requires only two people and 1 hour to finish installing.

- The Glass SPD system will be delivered to you in mere 20 days, whereas the Stainless Steel SPD system takes around 60 days or more to get delivered.

- The Glass SPD system is much lighter in weight, occupies smaller space, and is quite easy to move as compared to the Stainless Steel SPD system.

- The Glass SPD system is transparent, and it self-adjusts the circumstances of an experiment a bit quickly, depending upon the situation.

- The Glass SPD system is considered much more durable than the Stainless Steel SPD system concerning anti-corrosion abilities.

- For the Research and Development procedure or the pilot procedure, the Glass SPD system works better, whereas, for large-scale production purposes, you can opt for the Stainless Steel SPD system.

Principle

In the liquid-liquid separation process, the Short Path Distillation System must be used;

- When the material’s boiling temperature is too high to evaporate?

- When boiling temperatures of 2 materials are too close to be separated clearly?

- When the material is sensitive to heat and easy go denatured in distillation?

- When a rectification process takes a long time but with the poor receiving rate?

Suitability

The Short Path Distillation System is also known as Molecular Distillation System. The Short Path Distillation System is exclusively a new substance separation technology that helps in separating liquid-liquid mixture under any temperature lower than the boiling point.

Short Path Molecular Distillation is highly suitable for the process of separating the substances that have a high boiling point, is sensitive to heat, and quite easy to be oxidized.

Advantages of Short Path Molecular Distillation

- Experience and Flavor, both are consumer-oriented advantages; however, for the producers, many other benefits come after they employ a Short Path Wiped Film Distillation method or a Short Path Distillation method.

- The other extraction or separation processes tend to use heated beakers. However, the continuous feed also grants your production a compelling degree of scalability, which is not an option for those with the batch mode stills.

- A higher rate of evaporation will allow you to capture more distillates. In contrast, the low processing temperatures ranging between 130-180°C also adds up to the fact that not many solvents are required to move the extracted material during the process.

- The Short Parth Molecular Distillation system will extensively separate cannabis into the highly concentrated CBD and THC distillates. The Short Path Distillation process may result in 99% pure cannabis distillates. Hence, if you wish to produce a purified CBD product, you are highly advised to opt for the Short Path Molecular Distillation process, as it is the commonly accepted method for such processes.

- The Short Path Distillation System is known for its sleek and compact design and is an ideal choice for those who want to use it for massive operations where significant quantities of multiple strains are extracted.

- Last but not least, all these machines are highly comfortable to work on and are fully automated in their functions.

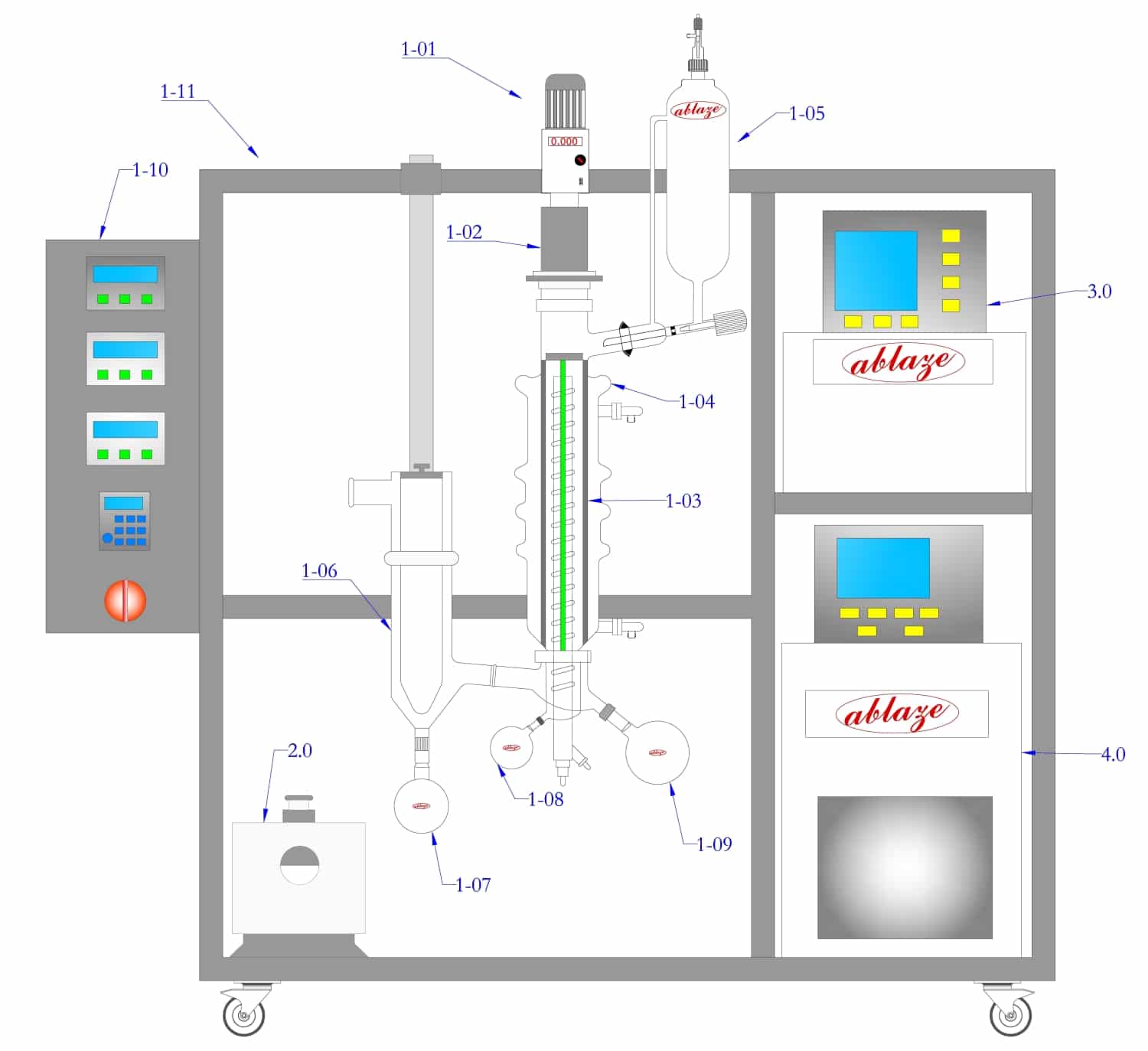

Diagram

Technical Specification

| Mark | Specification |

| 1 | Short Path Distillation System FMD Model Series |

| 01-Jan | Frequency Conversion Deceleration Motor |

| 01-Feb | Magnetic Force Transmission & Completed Sealing System |

| 01-Mar | Wiped Film Forming System |

| 01-Apr | Short Path Distillation Main Body |

| 01-May | PTFE Double Vacuum Valve- Dropwise Constant Pressure Feeding Funnel |

| 01-Jun | Cold Trap |

| 01-Jul | Waste Solution Receiving Flask |

| 01-Aug | Light Component Receiving Flask |

| 01-Sep | Heavy Component Receiving Flask |

| 01-Oct | Electrical Control Cabinet |

| 01-Nov | Removable Stainless-Steel Square Tube |

| 2 | Vacuum System |

| 3 | Constant Temperature Heating Circulator System |

| 4 | Low-temperature Cooling Circulator System |

Dimension Table

| DESCRIPTION | ASPD 60 | ASPD 80 | ASPD 100 | ASPD 150 | ASPD 200 | ASPD 230 | |

| Effective Evaporation Area | m2 | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

| Condensation Area | m2 | 0.1 | 0.18 | 0.3 | 0.4 | 0.5 | 0.65 |

| Barrel Inner Diameter | mm | 60 | 80 | 100 | 150 | 190 | 220 |

| Constant Pressure Feeding Funnel | L | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Processing Flow | L/H | 0.1~2.0 | 0.3~4.0 | 0.5~5.0 | 1.0~8.0 | 1.5~10.0 | 2.0~15.0 |

| Motor Power | W | 120 | 120 | 120 | 120 | 120 | 200 |

| Max Rotation Speed | rpm | 450 | 450 | 450 | 450 | 300 | 300 |

| Cold Trap | ml | 500 | 500 | 1000 | 1500 | 2000 | 2000 |

| Waste Solution Receiving Flask | ml | 500 | 500 | 1000 | 2000 | 2000 | 3000 |

| Light Component Receiving Flask | ml | 1000 | 1000 | 2000 | 5000 | 10000 | 10000 |

| Heavy Component Receiving Flask | ml | 1000 | 1000 | 2000 | 3000 | 5000 | 5000 |

| Vacuum System | L/S | 4 | 4 | 4 | 4 | 8 | 8 |

| Constant Temperature Heating Circulator System | Cº | 5L/300℃ | 10L/300℃ | 10L/300℃ | 10L/300℃ | 20L/300℃ | 30L/300℃ |

| Low-temperature Cooling Circulator System | Cº | 5L/-10℃ | 5L/-10℃ | 5L/-10℃ | 5L/-10℃ | 20L/-10℃ | 30L/-10℃ |